Complete Collection of

D.L.S. Press Releases

Click a year below to expand the view

January 10, 2023

Testing and consulting compliance organization receives nationwide 7th consecutive ACIL Customer Quality Service Award

This award sets D.L.S.’s laboratory apart from other laboratories by demonstrating their continued commitment to quality testing and customer service. This continuous improvement program was developed to address industry quality issues and recognize those individual testing laboratories with exemplary quality performance. It provides companies and industry with a comprehensive mechanism to evaluate testing laboratories. Participants commit to ensuring data integrity, meeting customers’ quality needs and setting performance standards for the testing laboratory industry. No other evaluation program ranks customer satisfaction with laboratory services and requires laboratory management to commit to a data integrity program. To become a participant, testing laboratories must distribute satisfaction surveys to customers, commit to an ethics program and submit a signed code of ethics.

D.L.S. supports Military, Aerospace, Avionics, Medical, Industrial, Consumer Product and Automotive markets on a global basis. It is an accredited ISO 17025 testing laboratory under the ANSI National Accreditation Board – ANAB. Additional details about D.L.S. testing services can be found at www.dlsemc.com or by contacting Jack Black at jblack@dlsemc.com.

January 14, 2022

D.L.S. Electronic Systems, Inc. Receives Nationwide 2021 ACIL Customer Quality Service Awards

On December 9th, 2021, D.L.S Electronic Systems, Inc. received three Quality Service Awards from the Washington, DC based American Council of Independent Laboratories (ACIL):

- Nationwide ACIL 2021 Customer Quality Service Award

- Special Recognition Award for Timeliness

- Special Recognition Award for Overall Customer Satisfaction

ACIL was developed in 1996 to address the industry’s quality issues and recognize those laboratories with exemplary quality performance. The Program provides laboratory data users with a mechanism to evaluate testing laboratories. Participants commit to ensuring data integrity, meeting customers’ quality needs and setting performance standards for the testing laboratory industry. No other evaluation program ranks customer satisfaction with laboratory services and requires laboratory management to commit to a data integrity program.

To become a participant, testing laboratories must distribute satisfaction surveys to customers, commit to an ethics program and submit a signed code of ethics. Participants in 2021 demonstrated an average timeliness of 3.6 out of a possible 4.0 and an overall customer satisfaction score of 3.8 out of a possible 4.0.

D.L.S. Electronic Systems is a Wheeling, Il based compliance testing and consulting organization, specializing in EMC/EMI, Environmental, Product Safety and Wireless testing and consulting, and provides service on a global basis. It is accredited by ANAB under ISO 17025 quality programs.

Additional details about D.L.S. testing services can be found at www.dlsemc.com. For further information, contact Jack Black at jblack@dlsemc.com.

October 14, 2020

D.L.S. Electronic Systems, Inc. Awarded TOP PERFORMER Status in ACIL Annual Quality Survey

D.L.S. Electronic Systems has been awarded TOP PERFORMER status for Customer Satisfaction by the American Council of Independent Laboratories-ACIL in their annual quality survey for 2020-2021. This prestigious award is the highest attainable level and based on feedback from customers and compared against all laboratories participating in the survey, and is in addition to the 2020-2021 Award for Demonstrated Ethics, Customer Service, and Overall Quality. This is the 5th year in a row that D.L.S. has been cited for their outstanding performance in customer service.

D.L.S. Electronic Systems is a Wheeling, IL based compliance testing and consulting organization, specializing in EMC/EMI, Environmental, Product Safety and Wireless testing and consulting, and provides service on a global basis. D.L.S. is accredited under the ISO 17025 quality program by ANSI National Accreditation Board-ANAB.

Additional details about D.L.S. testing services can be found at www.dlsemc.com.

May 5, 2020

D.L.S. is Open with Remote Access Video Monitoring

D.L.S. is open and providing testing for EMC, Wireless, Environmental and Product Safety compliance. Maintain social distancing by using the D.L.S. XXPRESS shipped testing program and our TestView interactive video process for real-time remote viewing of ongoing tests. A demonstration video can be seen here.

D.L.S. has taken precautions and continues to monitor health conditions to ensure a safe environment for customers and employees. For more information, contact Jack Black at jblack@dlsemc.com.

September 3, 2019

Gravel Impact Testing

D.L.S. performs gravel impact testing to several industry standards including those found in Automotive, Military, Aviation, and Industrial applications. D.L.S. performs these tests on equipment, components, materials, coatings, and other surface preparations. D.L.S. offers a complete environmental and climatic testing program that includes MIL-STD 810, 202, 32440, RTCA DO-160, SAE, IEC, ISO, ISTA, ANSI, ASTM and other global compliance requirements.

More information can be found at Environmental Testing.

May 21, 2019

Automotive Environmental/Mechanical Testing

D.L.S. Electronic Systems, Inc. supports Environmental/Mechanical testing for automotive and related transportation industry applications, such as electrical and electronic controls and modules, entertainment systems, lighting, inherent safety, materials, and other automotive equipment. This includes controls, components, modules and sub-assemblies for motorcycles, scooters, trucks, construction, off-road, and agricultural equipment. Testing includes temperature extremes, climatic conditions, mechanical, and chemical/fluid resistance.

D.L.S. is accredited to ISO 17025 and provides OEM, SAE, CE-E-Mark and other national agency compliance testing services, for both OEM and aftermarket devices and supports development work, pre-compliance, mitigation, troubleshooting and consulting services.

More information can be found at Automotive Environmental Testing

April 23, 2019

MIL-STD 810G-506.6 Blowing Rain Testing

D.L.S. performs the entire environmental suite of tests found in MIL-STD 810 G, method 506.6, procedures 1, 2, and 3. Included are rain and blowing rain, exaggerated, and drip. These tests are often performed as part of an environmental testing program that includes other climatic or mechanical tests found in MIL-STD 810 G, in addition to MIL-STD 461 EMI related tests.

More information can be found at MIL-STD 810 Blowing Rain Testing

March 26, 2019

Combined Temperature/Altitude/Humidity Testing

D.L.S. Conformity Assessment has expanded testing capabilities to include combined Temperature/Altitude/Humidity testing with levels up to 100,000 feet, – 68° C to + 177° C, with humidity, all at the same time. Testing is compliant to RTCA DO-160, Sec 4, MIL-STD 810, and other industry standards. D.L.S. offer a full environmental testing program that includes climatic and mechanical testing services.

More information can be found at RTCA DO-160 Temperature and Altitude Testing

March 5, 2019

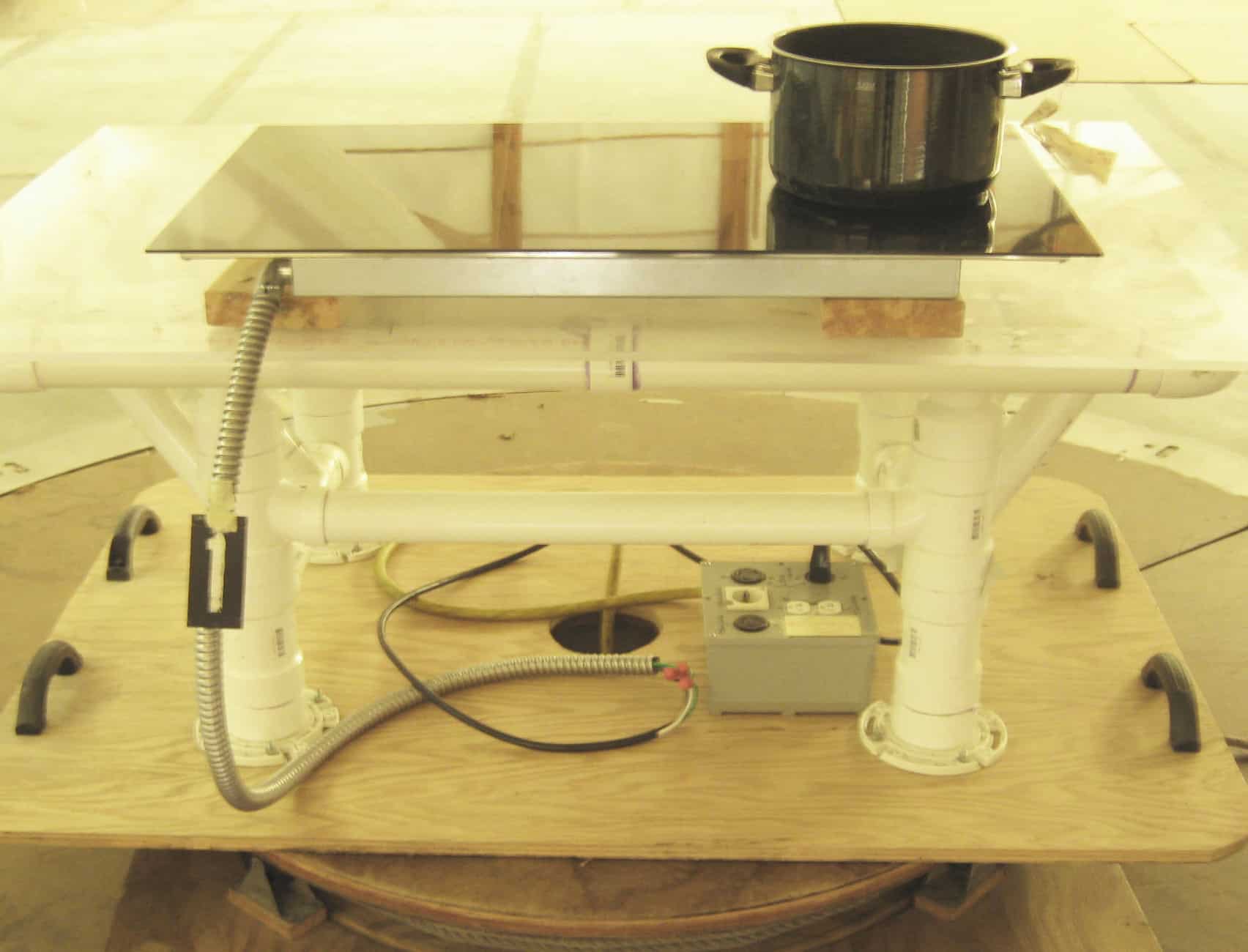

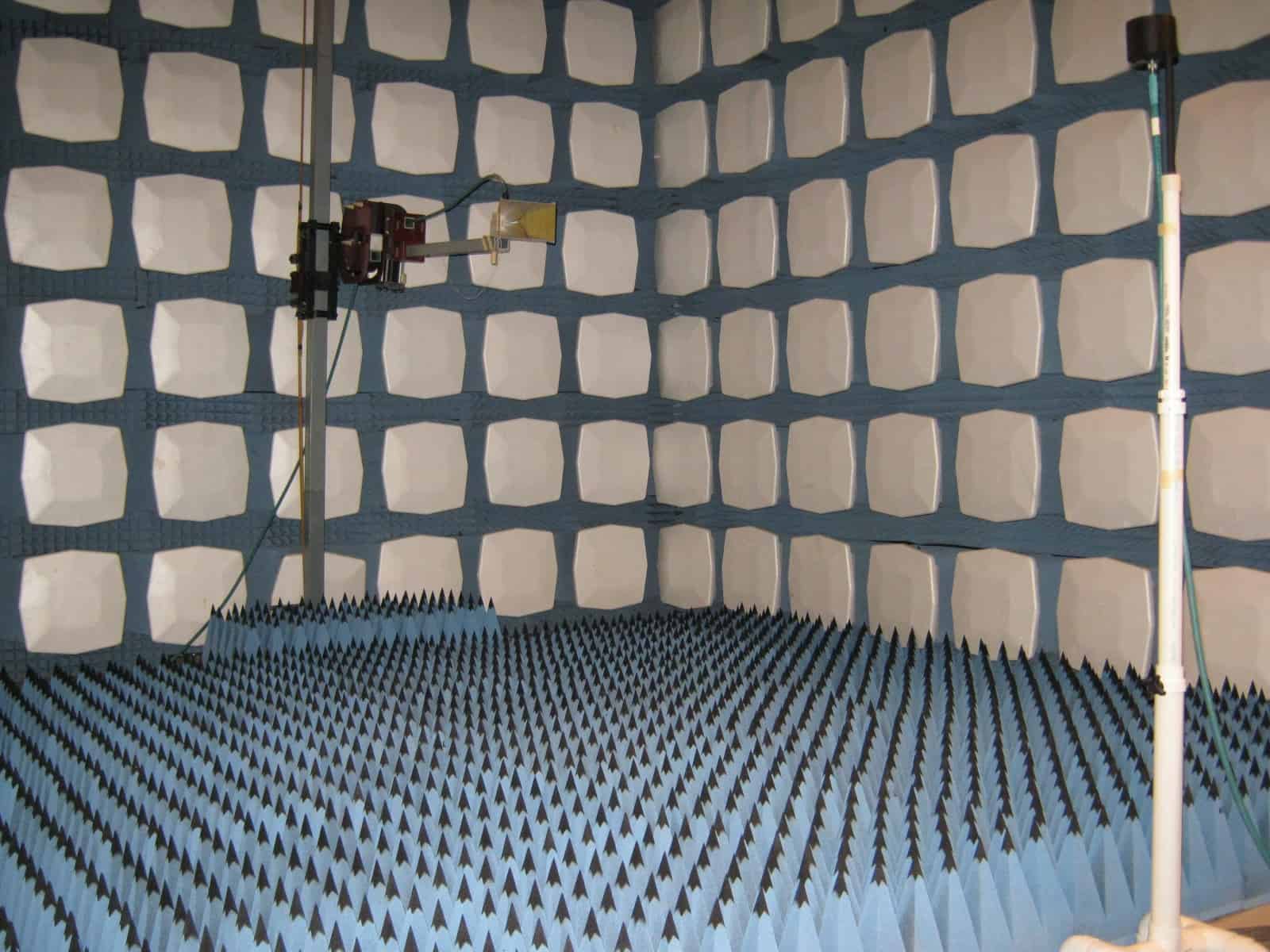

30-Meter Far Field EMI Testing

D.L.S. performs 10-meter and 30-meter distance far-field EMC testing to support formal EMC certifications where 30-meter test distance is a specific requirement at 9 kHz to 30MHz frequencies. This testing can be used to show compliance for FCC part 18, FCC part 15, and other global emissions standards. Products include induction cooktops, restaurant equipment, medical devices, low-frequency transmitters, industrial equipment, and other devices that utilize RF energy for functional purposes. More information can be found at 30 Meter Far-field Testing.

February 5, 2019

New Standards: D.L.S. Wireless and Radio Testing Capabilities

D.L.S. is formally accredited for wireless device compliance testing for EU, FCC and ISED Canada, including the newest standards for the Radio Equipment Directive and the EMC Directive. This includes unlicensed transmitters & receivers, RFID, Bluetooth, ZigBee, WLAN, Wi-Fi, NFC, and other wireless communication technologies including emerging IoT (Internet of Things) platforms. D.L.S. offers a complete service for testing, consulting and regulatory approvals on a global compliance basis. More information at Wireless Device Testing

October 9, 2018

D.L.S. Electronic Systems, Inc. Receives ACIL Customer Quality Service Award

On October 3, 2018 the American Council of Independent Laboratories (ACIL) announced recipients of the nationwide ACIL Customer Quality Service Award for 2018-2019, and once again D.L.S. Electronic Systems received this award.

Developed in 1996 to address the industry’s quality issues and recognize those laboratories with exemplary quality performance, the Program provides laboratory data users with a mechanism to evaluate testing laboratories. Participants commit to ensuring data integrity, meeting customers’ quality needs and setting performance standards for the testing laboratory industry. No other evaluation program ranks customer satisfaction with laboratory services and requires laboratory management to commit to a data integrity program.

To become a participant, testing laboratories must distribute satisfaction surveys to customers, commit to an ethics program and submit a signed code of ethics. Participants receiving the award demonstrated an average timeliness of 3.5 out of a possible 4.0 and an overall customer satisfaction score of 3.7 out of a possible 4.0.

D.L.S. Electronic Systems is a Wheeling, IL based compliance testing and consulting organization, specializing in EMC/EMI, Environmental, Product Safety and Wireless testing and consulting, and provides service on a global basis. It is accredited under the NVLAP and ANAB 17025 quality programs.

Additional details about D.L.S. testing services can be found at www.dlsemc.com.

September 28, 2018

Appliances Need to Meet New IoT Related Standards

Appliances that incorporate the latest Internet of Things technology and wireless access need to meet the new Radio Equipment Directive for the European Union, which takes precedence over other directives. Contact D.L.S. Electronic Systems at Radio Equipment Directive (RED) Updates for Wireless and Similar Products.

September 11, 2018

D.L.S. Streamlines RFID Testing for FDA EMC Compliance Requirements on Medical Devices

The FDA has established compliance criteria for electromagnetic compatibility that now includes protection against exposure to RFID devices. This recent requirement is related to potential risks due to the increase of RFID equipped devices to a level that the FDA has determined warrants inclusion on current FDA applications. AIM 7351731, an FDA recognized standard for the healthcare industry, has been established to determine safe limits for medical devices with respect to RFID exposure.

RFID protection compliance testing is over and above testing requirements found in the IEC 60601-1-2, and is being mandated by the FDA on their most recent acceptance criteria for medical devices and equipment.

D.L.S. Electronic Systems has developed a streamlined program that supports formal compliance testing for medical devices and equipment when exposed to electromagnetic phenomena related specifically to RFID enabled devices, as required by the FDA.

D.L.S. engineering staff offers specialized guidance on the testing of non-implantable medical devices to determine if they are immune to emissions from radio frequency identification (RFID) systems. Test protocols are included for the major commercial implementations of RFID as standardized by ISO, including LF, HF, and UHF RFID. Both active and passive ISO RFID standards are covered. The D.L.S. program provided addresses all medical devices and how to test for immunity to emissions from RFID systems.

Learn more about the new immunity RFID requirements established by the FDA and required for future medical products

April 16, 2018

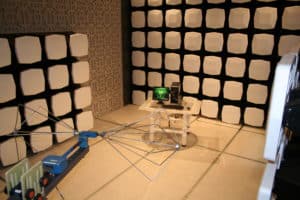

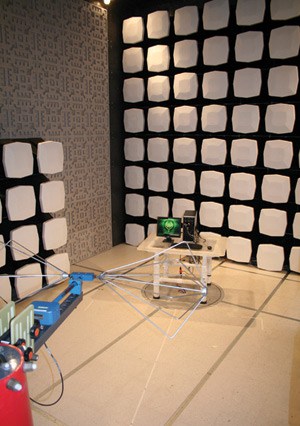

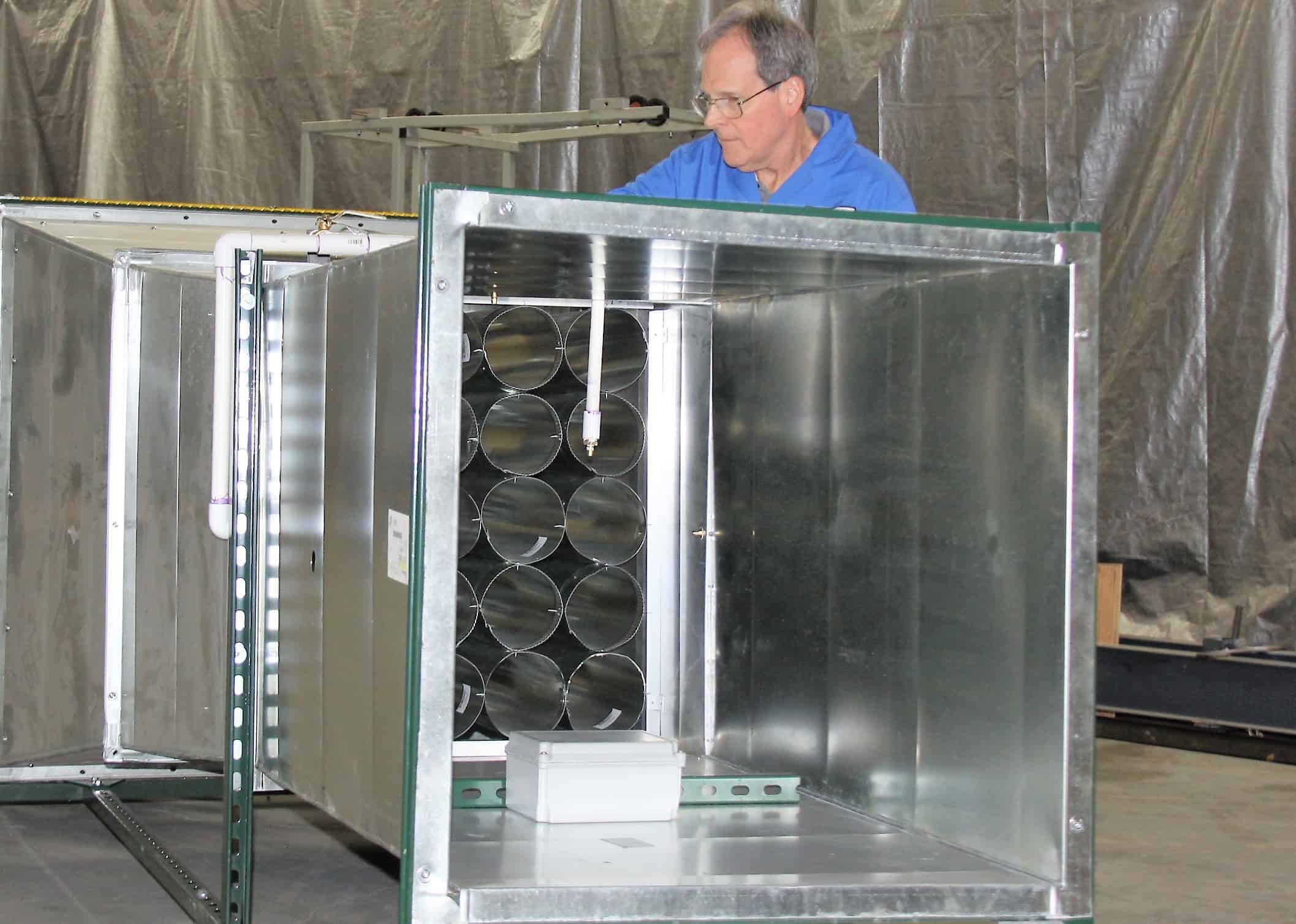

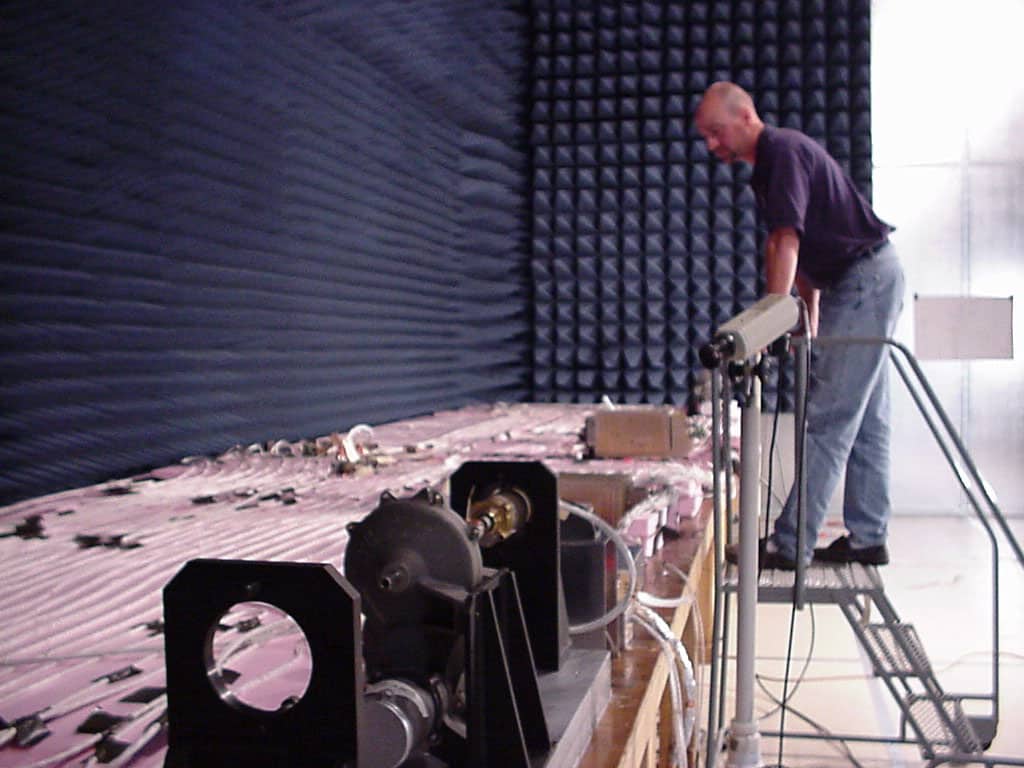

D.L.S. Expands with New (16th) EMI Testing Chamber

To meet customer demand and to increase flexibility, D.L.S. has added a new chamber dedicated to support MIL-STD and RTCA DO-160 EMI testing. With this new chamber, the 16th at the D.L.S. facilities in Wheeling, IL, we are able to support current demand for MIL-STD 461 and RTCA DO-160. This allows us to offer immediate testing availability, and additional flexibility for other testing requirements such as FCC, ICES, Automotive, ETSI, EN, IEC, KN and other global EMI/EMC testing requirements.

D.L.S. is a fully accredited testing organization under the ISO 17025 guidelines by NIST, under the NVLAP accreditation program, which is also an ILAC signatory and globally recognized program. D.L.S. offers a one-stop full service compliance program, with environmental testing, including MIL-STD 810, MIL-STD 202, RTCA DO-160, and other global testing standards.

September 22, 2017

D.L.S. receives Special Recognition Award

On October 2-5, 2017 in Portland Oregon, ACIL (American Council of Independent Laboratories) will be announcing the 14 laboratories receiving the 2017 ACIL Customer Quality Service Award. To be included, a laboratory must receive 3.7 points out of 4 for Overall Customer Satisfaction. We are happy to announce that D.L.S. Electronic Systems, Inc. has once again been included on this list. In addition, D.L.S. has received a Special Recognition Award for Overall Customer Satisfaction for placing in the top fifth of the participants.

January 17, 2017

Free 45-minute one-on-one review

of YOUR product

Spend two days learning how to design your product for EMC/EMI, followed by a day-long workshop applying the rules and regulations to real, life products. Then bring your current prototype, drawings or board layout to a free 45-minute personal consultation with an instructor or his associate to discover any EMC/EMI problems while still in the design stage, thus saving you time and money. Learn to apply the theory you have just learned to your own product under the guidance of an EMC professional.

EMC By Your Design

An EMC Practical Applications Seminar/Workshop

April 25-27, 2017

Northbrook, IL

For details call 847-537-6400.

December 13, 2016

D.L.S. Electronic Systems, Inc. receives ACIL Customer Quality Service Award

The American Council of Independent Laboratories has named D.L.S. Electronic Systems recipient of the ACIL Customer Quality Service Award for 2016-2017. This award is based on a comprehensive client survey of key quality related issues, including the integrity of data, meeting customer’s service needs, technical expertise, timeliness, value, and overall satisfaction in comparison to other industry participants.

D.L.S. Electronic Systems is a Wheeling, IL based compliance testing and consulting organization, specializing in EMC/EMI, Environmental, Product Safety and Wireless testing and consulting, and provides service on a global basis. It is accredited under the NVLAP and ANAB 17025 quality programs.

June 1, 2016

Guest lecturer and author of latest EMC design book joins D.L.S. teaching team for October seminar

Michel Mardiguian, principal author of Controlling Radiated Emissions by Design, will be joining Donald L. Sweeney and staff in teaching the October 4-6, 2016 EMC By Your Design seminar in Northbrook, Illinois. The instructors have more than 100 years of combined EMC experience.

Michel, an IEEE Senior Member, has worked as an EMC Specialist for IBM and was the French delegate to the CISPR Working Group, which became CISPR 22, the root document for FCC 15-J and European EN55022. Michel has taught EMC seminars in the U.S. and worldwide to thousands of engineers and currently is a private consultant in France. He has written numerous books and papers on EMC. A major project he was involved with was the EMC for the English Channel Tunnel.

EMC By Your Design is a practical applications seminar and workshop consisting of lectures, discussions, a hands-on-workshop, a large notebook of slides, take-home proprietary EMC design software, and individual design evaluations of your product. You will also receive an autographed textbook, Controlling Radiated Emissions by Design by Michel, with contributions by the D.L.S. teaching team.

For more information call 847-537-6400.

September 22, 2015

Exporting your product may be complex during the “no-transition period” of the new European Directives

The day you “place your product on the market” is what decides whether you must comply with the old or new European EMC or LVD Directives. Therefore, two shipments of the same product shipped and “placed on the market” a day apart will have to meet two different requirements. The definition of “placing on the market” is complex and is not the same as “making available.”

D.L.S. Electronic Systems, Inc. has established a webpage at www.dlsemc.com to help you navigate through this “no-transition period”. This website gives detailed information on:

- The latest updates on the EMC, LVD (Safety), R&TTE/RED and other Directives

- Guidance through which directive to use when

- Specifics of the New Low Voltage Directive (LVD)

- D.L.S.’s suggested steps you will need to take, such as generating a new DoC.

This website will keep you updated on the Commission’s additional significant changes so your product will have an orderly placement in the European Marketplace during 2015, 2016 and 2017. For more information call 847-537-6400.

June 16, 2015

How to Save Money on Compliance Testing

By Donald L. Sweeney

Having your final product fail its compliance test can be costly. Redesigning or adding fixes can be expensive and time consuming, possibly delaying your product to market. How can this additional cost be easily avoided? I can think of three ways.

- Take your product to your test lab early in the design stage so they can point out any potential problems, thus avoiding the expensive fixes or redesigns of a final product.

- Take an EMC Design seminar to become aware of future EMC pitfalls. In the seminar, you will learn the latest updates of current rules and regulations, common reasons why products fail their compliance tests, and problem solving techniques to implement early in the design stage.

- Take the EMC By Your Design Seminar in Northbrook, IL, October 6-8, 2015 and receive a $300 discount for new attendees who register by September 15 or a 50% discount for those who took the class using a prior version of the current textbook Controlling Radiated Emissions by Design, 3rd Edition, who register by September 15.

More information can be found by calling 847-537-6400.

March 31, 2015

ITAR Certified Testing and Consulting Services by D.L.S. Electronic Systems, Inc.

D.L.S. Electronic Systems, an ITAR certified organization, performs compliance testing for EMC, Environmental, Power Quality, Acoustical and Electrical applications for devices and equipment that fall under the The International Traffic in Arms Regulations ( ITAR ) program. Services include testing to MIL STD 461, MIL STD 810, MIL STD 1399, MIL STD 704, MIL STD 83528, MIL STD 202, MIL STD 750 and MIL STD 883, as well as senior level engineering design consulting with senior level iNARTE certified engineers. More information can be found at the D.L.S. web site, www.dlsemc.com.

January 20, 2015

Learn to Design EMC For Your Product

EMC by Your Design

An EMC Practical Applications Seminar and Workshop

by Donald L. Sweeney, Roger Swanberg & Tim Lusha

Using Latest EMC Textbook

Controlling Radiated Emissions by Design

published in 2014 by Michel Mardiguian

contributed to and edited by Donald L. Sweeney

| Textbook Includes: |

|

| Also Using: |

|

Tues. April 14 – Thurs. April 16, 2015

Hilton Hotel, Northbrook, IL

847-537-6400

September 30, 2014

D.L.S. Updates NVLAP Accreditation for World Wireless Testing Services

D.L.S. Electronic Systems, Inc. has updated its NVLAP Accreditation for Wireless Testing and its recognition for various MRA’s through NIST. This program consists of formal approval for wireless communication devices and intentional radiators subject to EMC regulations and includes EMC testing and certification for FCC (Federal Communications Commission), Industry Canada, the European Union (ETSI), Australia, and many other worldwide markets. D.L.S. offers a wide variety of short range wireless communication compliance services on devices that incorporate technologies such as Bluetooth®, Zigbee®, and Wi-Fi™.

D.L.S. offers comprehensive one-stop-shopping for worldwide markets for EMC, Product Safety, Environmental, Military and Aviation testing and consulting. For more information, please contact Jack Black at jblack@dlsemc.com or visit Wireless Device Testing.

July 2, 2014

Congressman Brad Schneider Visits D.L.S. Electronic Systems, Inc. Facility in Wheeling, IL

Congressman Brad Schneider (D-IL-10) talks with D.L.S. Electronic Systems, Inc. employees.

Congressman Brad Schneider (D-IL-10) visited D.L.S. Electronic Systems, Inc. in Wheeling, IL to witness firsthand the skilled jobs and businesses that the production of U.S. Navy amphibious warships brings to the region and to the local economy. D.L.S. provides electromagnetic compatibility (EMC), environmental, mechanical and climatic testing, along with power quality testing for equipment used on U.S. Navy amphibious warships.

During his tour, Congressman Schneider met with the employees at D.L.S. to discuss the unique skills they contribute to the industrial base that supplies parts and products critical to the U.S. Navy’s amphibious warship program.

“I was pleased to have the opportunity to be able to meet the hardworking employees at D.L.S. Electronic Systems and to develop a greater understanding of the significant contributions they make to our local economy and our national defense,” said Congressman Schneider. “As a member of the Committee on Small Businesses, I understand the importance of facilities like this one to a prosperous local economy and a healthy industrial base to guarantee that our soldiers deployed have the equipment they need to fully accomplish their mission.”

“Hosting Congressman Schneider at our facility gave us the opportunity to showcase the work we do at D.L.S. Electronic Systems and highlight how our business depends on a fully funded U.S. Navy amphibious warship construction program. We look forward to Congressman Schneider’s continued leadership on funding amphibious warships at a level that will maintain our nation’s strength,” said Jack Black, Business Development Manager at D.L.S. Electric Systems, Inc.

For more information email Jack Black at jblack@dlsemc.com, or call 847-537-6400.

June 3, 2014

Latest EMC Book, published 2014:

Controlling Radiated Emissions by Design, 3rd Edition

Contributed to and Edited by Donald L. Sweeney

with Worldwide Standards Updated

Design Techniques for Controlling Radiated Emissions (now called Controlling Radiated Emissions by Design) has been considered by Donald Sweeney to be the ideal textbook for his EMC By Your Design Seminars since 1992, when the book was first published. And now in its new third edition, Don is pleased to have contributed to many parts of the book, including updating the Worldwide Standards and many of the graphics, as well as editing the entire book. All 13 chapters have been revised and updated addressing newer technologies, especially the updating of clock speeds and the examples worked out in the book. A special feature of the book will be a link to a continuous update of world standards and requirements as they change.

Those who have previously attended a D.L.S. Seminar using the 1st or 2nd edition of the book, and who would like to take a refresher course using the new book, will be given a 50% discount from the October 2014 seminar price.

An EMC Practical Applications Seminar and Workshop

Tues. Oct. 7 – Thurs Oct. 9, 2014

Northbrook, IL

For more information, visit call 847-537-6400.

May 27, 2014

D.L.S. Environmental Testing Consolidates Under ACLASS 17025 Accreditation

D.L.S. Conformity Assessment announces the consolidation of their environmental testing services under the ACLASS 17025 accreditation program overseen by ANSI. This globally accepted program covers environmental testing under MIL-STD 810, MIL-STD 202, RTCA DO-160, ANSI, ASTM, IEC, ISTA, NEMA, and SAE standards and includes but is not limited to vibration, temperature extremes, humidity, shock, salt spray, acceleration, altitude, sand and dust, rain, chemical exposure, waterproofness, flammability, decompression, and icing. Testing services are offered at their centrally located facilities in Wheeling, IL, and are complementary to the existing EMC and Product Safety services offered by D.L.S. More information can be found at Environmental Testing.

Vibration Testing at D.L.S.’s Environmental Test Lab

January 7, 2014

D.L.S. Expands Environmental Testing

Altitude Testing at D.L.S. Wheeling East Campus

D.L.S. Electronic Systems, Inc. is proud to announce their expansion of in-house MIL STD 810 and DO-160 Environmental Testing Services. They have extended their capabilities to include Sand and Dust Testing, as well as Vibration and Shock Testing. They also test for Temperature, Humidity, Altitude, Acceleration and Salt Spray.

For further information email Jack Black at jblack@dlsemc.com or call him at 847-537-6400. Also visit Environmental Testing.

D.L.S. is a full service Compliance Laboratory for military, aerospace and avionics testing.

December 10, 2013

Latest EMC Book Now Available

Design Techniques for Controlling Radiated Emissions, 3rd Edition

By Michel Mardiguian

Contributed to and Edited by Donald L. Sweeney

with Worldwide Standards Updated

Design Techniques for Controlling Radiated Emissions has been considered by Donald Sweeney to be the ideal textbook for his EMC By Your Design Seminars ever since 1992, when it was first published. He is now excited to announce he will be using Michel Mardiguian’s new 3rd Edition in his April 8-10, 2014 seminar. All 13 chapters have been revised and updated addressing the newer technologies that have come along, especially the updating of clock speeds and the examples worked out in the book. Don has contributed to many parts of the book, including updating the Worldwide Standards and many of the graphics, as well as editing the entire book. A special feature of the book will be a link to a continuous update of world standards and requirements as they change.

Those who have previously attended a D.L.S. Seminar using the 1st or 2nd edition of the book, and who would like to take a refresher course using the new book, will be given a 50% discount from the April 2014 seminar price.

For more information call 847-537-6400.

D.L.S. is also proud to announce that Tim Lusha is joining our team of seminar instructors. Tim has been with D.L.S. for the past 17 years. He has four iNARTE certifications: EMC Engineer, EMC Laboratory Engineer, EMC and ESD Technician. He is a current member of RTCA/DO-160, IEEE and ESDA. Tim has worked at D.L.S.’s Wisconsin facility involved in FCC, EC and VCCI commercial requirements as well as measurement uncertainty, transmitters and calibrations. He is presently at our Wheeling location immersed in MIL STD 461 and DO-160 topics, custom test setups, software programs and networks for lightning and related testing. Tim is a graduate of the Milwaukee School of Engineering (MSOE) Milwaukee, WI in addition to graduate coursework in engineering and other courses in mechanical design.

July 23, 2013

Brainstorm: Electromagnetic Compatibility

By Bill Stumpf, as seen in Wireless Design & Development Magazine’s

Brainstorm Question, July 2013

What are the most popular trends you see in EMC, and how do these trends pave the way for the reduction in electromagnetic interference?

I see some trends in EMC that could reduce electromagnetic interference (EMI), and some that could increase it. Engineers seem to be better educated in the process of good EMC design, thanks to classes such as D.L.S.’s EMC By Your Design seminars. Circuits that are designed and laid out correctly, proper termination of shielded cables, and well designed enclosures all contribute to lower interference from digital electronics. However, there are two trends that have the potential to increase EMC interference.

The first is related to digital technology. Circuits and microprocessors continue to increase in operating speed, switching power supply designs strive to be more efficient and therefore more prone to higher emissions, and devices are ever more complex laden with multiple functions. The second is the proliferation of products that employ single or multiple wireless communication devices. Everyone wants to operate without wires, and more frequency bandwidth is being opened up for wireless communication.

Adding to the mix is that certified RF modules are easy to come by these days, and the integrator may not understand the possible effects of operating multiple radios in one product or in close proximity with other electronic products or wireless devices.

August 5, 2013

Wireless Qi Certification

From Evaluation Engineering’s 2013 IEEE Symposium Preview, August 2013

D.L.S. Conformity Assessment, Inc. announces new Wireless Power Charging Compliance Program including Qi Certification through the Wireless Power Consortium

D.L.S. offers the prestigious Qi compliance mark under authority from the Wireless Power Consortium for wireless charging applications. They offer a global compliance package that, in addition to the formal Qi certification, includes:

- interoperability

- wireless transmitter and receiver testing under FCC Part 15 and FCC Part 18 for North America, and the EMC and R&TTE Directives for the European Union

- Product Safety testing and certification for North America and Europe.

The recent introduction to the market of “inductive” wireless chargers and wireless power pads has created some misunderstanding and misapplication of EMC and Product Safety regulations.

How these regulations apply to these devices depends on how the devices operate at various frequencies and whether or not there is any wireless communication present. Careful attention must be taken to ensure that the correct regulations are applied and tested to, and the correct procedures for regulatory compliance have been followed.

Each different device’s application, use, and operation must be reviewed before the proper regulations can be determined and applied. Many of these devices will require that the full administrative and technical requirements of the North American standards and European Union Directives be applied, while others may require minor compliance consideration.

If you are planning to market a wireless power or charging product, please stop by Booth 812 or find us at www.dlsemc.com or call us at 847-537-6400. Let our experience with testing and certification of a number of these devices help you determine your compliance needs.

We offer a full compliance program for North America and the European Union, including the UL Product Safety mark for North American use, and the European CE Mark for compliance to EMC, R&TTE, and Low Voltage Directives.

June 19, 2013

Electromagnetic Interference in Device Design

By Donald L. Sweeney, as seen on the Medical Design Technology blog

The greatest obstacle to success in the design of a device is that often times the design engineer overlooks the need to keep electromagnetic interference in mind when he designs his device. When a product is not in compliance, it can be interfered with by radio waves emitting from other electronic devices in the home, causing the product to malfunction. Also the waves his product emits can interfere with other medical devices being used causing them to malfunction. To avoid this interference between devices, the design engineer’s finished product must pass a regulatory compliance test. If it fails this test, the design engineer will find it costly and time consuming to redesign his product or to add fixes to bring it into compliance.

January 7, 2013

Save Money

Shorten your compliance testing time by learning how to design for EMC

EMC By Your Design

An EMC Practical Applications Seminar and Workshop

Tues. April 23 – Thurs. April 25, 2013

Hilton Hotel, Northbrook, IL

847-537-6400

Learning how to design your product so that it complies with EMC regulations can save you from having a finished product that fails during its regulatory compliance testing. Re-designing or adding fixes to a failed product can be expensive and time consuming. By taking the EMC by Your Design Seminar, you will learn the fundamentals of electro-magnetic compatibility, including understanding the many EMC regulatory requirements such as FCC, CE, US Military, RTCA-DO-160 and those of most foreign countries. You will learn the methodology of how to minimize EMC problems, starting with the design process through final testing and approval, all of which will be brought to life through hands-on practical application to real life products. Also included will be a guided tour of the largest independent EMC and Product Safety facility in North America.

This newly updated curriculum was developed by Donald L. Sweeney and his associates. It includes how an electronic circuit becomes a radio transmitter, how the physics of even the simplest devices such as capacitors, inductors and shielding can help or hinder compliance and how to control the design to minimize emissions. Students will be lead step-by-step through sample calculations, be introduced to take-home proprietary software and be led through trouble shooting a product that does not meet the requirements. Additionally, attendees will be offered an exclusive, hands-on personal consultation with the instructor or a member of his technical staff to apply what has been learned to their specific product, possibly saving tens or hundreds of thousands of dollars in reduced testing, reduced time to market and reduced final product cost.

January 14, 2022

D.L.S. Electronic Systems, Inc. Receives Nationwide

2021 ACIL Customer Quality Service Awards

On December 9th, 2021, D.L.S Electronic Systems, Inc. received three Quality Service Awards from the Washington, DC based American Council of Independent Laboratories (ACIL):

- Nationwide ACIL 2021 Customer Quality Service Award

- Special Recognition Award for Timeliness

- Special Recognition Award for Overall Customer Satisfaction

ACIL was developed in 1996 to address the industry’s quality issues and recognize those laboratories with exemplary quality performance. The Program provides laboratory data users with a mechanism to evaluate testing laboratories. Participants commit to ensuring data integrity, meeting customers’ quality needs and setting performance standards for the testing laboratory industry. No other evaluation program ranks customer satisfaction with laboratory services and requires laboratory management to commit to a data integrity program.

To become a participant, testing laboratories must distribute satisfaction surveys to customers, commit to an ethics program and submit a signed code of ethics. Participants in 2021 demonstrated an average timeliness of 3.6 out of a possible 4.0 and an overall customer satisfaction score of 3.8 out of a possible 4.0.

D.L.S. Electronic Systems is a Wheeling, Il based compliance testing and consulting organization, specializing in EMC/EMI, Environmental, Product Safety and Wireless testing and consulting, and provides service on a global basis. It is accredited by ANAB under ISO 17025 quality programs.

Additional details about D.L.S. testing services can be found at www.dlsemc.com. For further information, contact Jack Black at jblack@dlsemc.com.

November 20, 2012

The Future of Medical EMC Testing

Editorial in Medical Design Technology November/December, 2012 issue

Recently a draft changing 60601-1-2 was circulated proposing some dramatic additions to medical immunity requirements. Over the years, medical equipment has had a primary concern that it functions properly in all the environments. This can mean life or death to a patient or even a worker.

At the 2002 IEEE EMC Symposium, examples were reported of wireless problems, such as cell phones causing an infusion pump to over infuse epinephrine, a defibrillator affected by a pager, a ventilator affected by a cell phone, etc. I once personally measured the field from a car cell phone at 50 Volts /meter so you can see how that could affect a medical device.

Many years ago the only standard available was known as MDS-201-0004 1979. This standard preceded most civilian EMC test standards and was used by our testing laboratory to simulate failure which occurred in the field by customers’ products. Using this standard we could recreate what was happening in the field. Once we had recreated it, we could then develop a solution.

I have always found the standard interesting as it not only contained the testing requirements but also the data recorded in the field for various environments. As an engineer, it not only told me what I had to do but why I needed to do the test and at what level.

When the European Community developed common EMC requirements for products starting with the proposals in 1989, we began to see standards written to cover many of the phenomena we had been seeing from the field. The earliest requirements for medical equipment were:

- IEC 801-2 Electro Static Discharge, the shock you get in the winter when you touch something.

- IEC 801-3 Radiated electric field 26 MHz to 1000 MHz, what you would see from a radio station or a walkie talkie.

- IEC 801-4 Fast Electrical Transients, the energy seen on power lines when contacts are opened for an inductive load.

These were relatively simple but a big beginning.

I remember how amazed I was when the home appliance standard EN 55014 came out with its update and introduced 801-5 lightning on power lines, 801-6 RF on power lines, 801-8 magnetic field testing and 801-11 sag surge and dropout. This, for a while, was more stringent than the requirements for Medical Equipment!

Today the 801’s have been replaced by Standards IEC 1000-4-2, 3, 4, 5, 6, 8 and 11.

With the draft being proposed, which is trying to stay ahead of the wireless communication technology, there are new frequencies and levels being proposed. Many of the new requirements take into account the emissions from the following new technologies:

- TERA 400/800

- GMS 460

- GSM 800/900/1900

- IDEN 820

- CDMA 850/1900

- DECT

- UMTS

- Bluetooth

- WLAN 802.77 a/b/g/n

- RFID

These are proposed to be tested to as much as 30 Volts /m.This draft has had hundreds of comments so will most likely be revised, but there will eventually be changes made to the standard to prevent serious accidents from occurring. These will require additional design consideration when planning a new product. It is recommended that the design engineers make themselves knowledgeable by understanding EMC design or taking a class before new products are developed.

November 13, 2012

New Wireless Power Charging Compliance Program including Qi Certification through the Wireless Power Consortium

As one of only two North American labs participating in the Qi Compliance program, D.L.S. Electronic Systems, Inc. in Wheeling, IL is offering Qi pre-compliance and formal certification as of December 15, 2012. This includes:

- interoperability

- wireless transmitter and receiver testing under FCC Part 15 and FCC Part 18 for North America, and the EMC and R&TTE Directives for the European Union

- Product Safety testing and certification for North America and Europe.

Background Information:

The recent introduction to the market of “inductive” wireless chargers and wireless power pads has created some misunderstanding and misapplication of EMC and Product Safety regulations.

How these regulations apply to these devices depends on how the devices operate at various frequencies and whether or not there is any wireless communication present. Careful attention must be taken to ensure that the correct regulations are applied and tested to, and the correct procedures for regulatory compliance have been followed.

Each different device’s application, use, and operation must be reviewed before the proper regulations can be determined and applied. Many of these devices will require that the full administrative and technical requirements of the North American standards and European Union Directives be applied, while others may require minor compliance consideration.

For more information, visit click here or call Jack Black at 847-537-6400.

October 1, 2012

How is D.L.S. influencing wireless medical devices?

Editorial in Medical Design Technology October, 2012 issue

At D.L.S. Electronic Systems, Inc. we influence wireless medical devices by helping to make sure they work when in the field, not interfering with other devices and not being interfered with from other devices. We do this by testing the wireless medical device to see that it meets the regulatory requirements set by the FDA and various world health and safety organizations. In addition, we help develop additional requirements for special cases. For example, one customer made a monitoring device that complied with regulatory requirements but because there were so many of these devices in the hospital, their individual emissions combined and were interfering with a leaky cable receiving antenna. We helped them get their device 20 dB below the limit so they could operate in this environment. (Multiple systems with the same emissions add 20 Log10 of the number of devices in dB. For example, 10 devices can be 20 dB higher than a single device.) At D.L.S. we not only test and consult for EMC and product safety for wireless medical devices; we also problem solve finding practical, workable solutions.

September 1, 2012

D.L.S. Electronic Systems, Inc. Medical Device Testing and Consulting Compliance Services

Editorial in Medical Product Manufacturing News (MPMN), September/October 2012 issue

D.L.S. offers a comprehensive program for compliance evaluation and testing for the new Third Edition Medical Device Standard IEC/EN/UL 60601-1 and 60601-1-2 for product safety and electromagnetic compatibility that became effective June 2012. D.L.S. provides testing, consulting and certification services for Medical Devices required to meets this standard.

Transitional Analysis

D.L.S. is offering a new transitional analysis program with respect to the new Third Edition update of the IEC 60601 requirements for compliance. This program provides a detailed review of testing previously performed to determine if it will show compliance to the new update. This comprehensive review involves not only previous test results, but the methodology and monitoring requirements when compared to a current ISO 14971 risk assessment. This program involves any previous testing, regardless of the performing testing laboratory, or the dates when the tests were performed. Manufacturers of medical devices must meet all the conditions for compliance to these new updated standards.

Risk Assessment Evaluation

All new compliance programs are subject to the risk assessment requirements found in ISO 14971. This new requirement is much more detailed and stringent than past compliance projects. The D.L.S. technical staff lends both guidance and assistance in the preparation, review, and formal presentation of the risk assessment that is mandatory for formal certification. The D.L.S. evaluation program involves not the only the risk assessment portion, but details the construction review of design and manufacture to insure an expedient testing program.

Early Design Evaluation

For new products coming to market, D.L.S. offers a comprehensive design review to identify non compliant design related issues. This evaluation is recommended at an early stage in the development process, so any potential changes to the equipment being reviewed would have the least possible impact to both cost and delivery of a final approved product. Experienced engineers perform this process working hand in hand with the manufacturer to insure the most process capable design solution.

Product Safety Testing

With the new Third Edition requirements, many manufacturers must have older products retested and new products tested to show compliance with these new standards. These standards include U.S., Canada, and IEC requirements. D.L.S. offers a comprehensive one stop approach that includes UL-cUL testing, combined with IEC testing for a global marketplace. This program includes all national deviations for the European Union to show CE safety compliance to the Medical Device Directive and other global requirements as well.

Electromagnetic Compatibility

D.L.S. offers Electromagnetic Compatibility Testing in one of the largest EMC testing laboratories in North America, with technical support provided by iNARTE certified engineers, for both emissions and immunity required for formal compliance and approval. Testing includes both radiated and conducted emissions, and well as radiated and conducted immunity tests for North America and IEC requirements, supporting a global marketplace.

Summary

D.L.S. offers one of the few places where detailed engineering support is provided at all stages of the compliance process, from initial design, to final formal compliance testing, and all steps in between. For 30 years, the value added D.L.S. service oriented staff has meet the aggressive demands of the immerging medical device marketplace, keeping pace with the latest in updates to the growing global compliance requirements.

May 29, 2012

Save Money

Shorten your compliance testing time

by learning how to design for EMC

EMC by Your Design

An EMC Practical Applications Seminar and Workshop

Tues. Oct 23 – Thurs. Oct. 25, 2012

Hilton Hotel, Northbrook, IL

847-537-6400

Learning how to design your product so that it complies with EMC regulations can save you from having a finished product that fails during its regulatory compliance testing. Re-designing or adding fixes to a failed product can be expensive and time consuming. By taking the EMC by Your Design Seminar, you will learn the fundamentals of electro-magnetic compatibility, including understanding the many EMC regulatory requirements such as FCC, CE, US Military, RTCA-DO-160 and those of most foreign countries. You will learn the methodology of how to minimize EMC problems, starting with the design process through final testing and approval, all of which will be brought to life through hands-on practical application to real life products. Also included will be a guided tour of the largest independent EMC and Product Safety facility in North America.

This newly updated curriculum was developed by Donald L. Sweeney and his associates. It includes how an electronic circuit becomes a radio transmitter, how the physics of even the simplest devices such as capacitors, inductors and shielding can help or hinder compliance and how to control the design to minimize emissions. Students will be lead step-by-step through sample calculations, be introduced to take-home proprietary software and be led through trouble shooting a product that does not meet the requirements. Additionally, attendees will be offered an exclusive, hands-on personal consultation with the instructor or a member of his technical staff to apply what has been learned to their specific product, possibly saving tens or hundreds of thousands of dollars in reduced testing, reduced time to market and reduced final product cost.

May 1, 2012

Once a new medical device idea is formulated, what is the critical first step to help ensure its success through to market launch?

Editorial in Medical Design Technology, May 2012 issue

To ensure its success through to market launch, a newly formulated medical device will need an early stage design review, addressing electromagnetic compatibility and product safety requirements. This review is a critical first step because it eliminates regulatory compliance design flaws and identifies applicable standards early in the design phase, thereby eliminating costly changes during testing of the final product and delays in the delivery of the new device. This early stage design review will cover worldwide EMC and Safety directives, including FCC, CE, UL, CSA, FDA, IEC, CCC, and other government and regulatory agencies. This review will allow the device to meet regulatory compliance in a time-efficient, cost-saving way during final testing. We have found by addressing EMC and Product Safety requirements early in the design stage, we have saved many medical manufacturers the cost, frustration, and loss of time of trying to add fixes and design changes to a product that is out of limits or that requires Product Safety changes.

September 20, 2011

D.L.S. now offers TestView™ Service

|  |

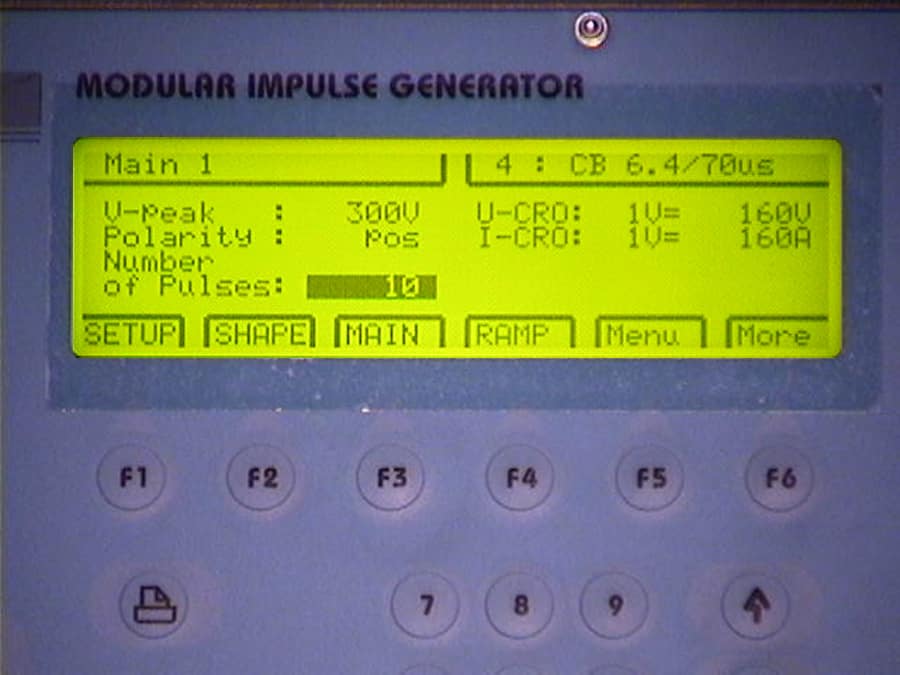

Save time and money by viewing, from your own office, your EMC compliance test being performed at D.L.S. Electronic Systems, Inc. in Wheeling, IL. TestView™ is a secure video system that enables clients to log in to D.L.S.’s test site from their own location and view their equipment being tested in real time. For example, a client could see a test engineer performing DO 160 Section 22 indirect lightning testing, as shown in the above photo. TestView™ allows the client to control the camera by making it zoom or pan to witness any part of their test at any time, as shown in the insert above. It is zoomed in on the test panel which shows the generator settings. For more information call Jack Black at 847-537-6400.

August 23, 2011

D.L.S. offers Early Design Evaluation program for medical products

In order to help a medical device meet regulatory compliance in a time efficient, cost-saving way, we created an Early Design Evaluation (EDE). This program incorporates an early stage design review and evaluation addressing the electromagnetic compatibility and the product safety requirements of electrical and electronic devices. This program covers world wide EMC and Safety directives, including but not limited to, FCC, CE, UL, CSA, ACA, FDA, FAA, IEC, CCC and other government and regulatory agencies. This process greatly reduces the time to market by eliminating design flaws and identifying applicable standards early in the design phase.

The EDE Four-Point Program:

Initial Review The initial review develops a brief description of the product or device, including its intended use.

EMC and Product Safety Compliance Review EDE Project leader and EDE Specialist review product or device for applicable EMC Directives and Standards, Review of individual standards, and Review Description of Testing Methodology.

EMC and Product Safety Design Evaluation Detailed analysis of the product or device for EMC and Product Safety issues by EDE EMC Specialist and Product Safety Specialist. Review of EMC and Product Safety design issues/solutions:

- Board/Component related

- Cable Related

- Enclosure Related

- System Related

A Final Report Is issued by EDE Project Leader. Specifically mentioned are recommendations in the areas reviewed and discussed. Included are proposals related to additional work needed for compliance to applicable standards.

Results We have found by addressing EMC and Product Safety requirements early in the design stage, we have saved many medical manufactures the cost, frustration, and loss of time of trying to add fixes and design changes to a product that is out of limits or that requires Product Safety changes.

July 7, 2011

UL approves D.L.S. Conformity Assessment, Inc.

for Safety Testing

Underwriters Laboratories has officially accepted D.L.S. Conformity Assessment, Inc., a subsidiary of D.L.S. Electronic Systems, Inc., into their Third Party Test Data Program. This program allows D.L.S. to test directly to UL standards for ITE, audio/video, medical devices and equipment, and laboratory test and measurement equipment for formal listing.

Manufacturers will be able to complete their EMC, Safety and Environmental testing requirements all under one roof, saving them time and allowing them to speed their product to market. This program provides for a formal UL listing for U.S. and Canadian safety standards.

June 14, 2011

Influencing Wireless Medicine

In response to Medical Design Technology’s question, “How are you influencing wireless medicine?” our Senior EMC Test Engineer and OATS manager, Bill Stumpf, responded with the following:

Wireless technologies have an important role in medical applications such as asset tracking (RFID), wireless controllers, patient monitoring, two-way radios, and wireless data transfer. It is imperative that manufacturers of these wireless medical devices address the issues and concerns relevant to the safe and effective use of radio frequency (RF) as required by the many Medical Standards and the hospital environment. As an Electromagnetic Compatibility and Product Safety lab offering testing, consulting, and certification of wireless devices, we get manufacturers through regulatory compliance hurdles. In this way we provide a streamlined process of getting new wireless medical technologies on the market in a timely and cost effective manner. By testing for RF emissions, Immunity to Interference, and Product Safety, we are helping to provide assurance that the wireless device will work reliably in the environment for which it is intended, and that it will be safe for the user and patient. As a test lab we are helping to make these wireless technologies available to the medical industry.

April 20, 2010

Now offered in New 3-Day Format

Tues. Oct. 26 – Thurs. Oct. 28, 2010

Hilton Hotel, Northbrook, IL

EMC by Your Design

An EMC Practical Applications Seminar and Workshop

Keeping the same important concepts & material

presented in a more condensed format including:

- Lecture, discussion and hands-on workshop

- 2 textbooks and large workbook of slides used in class

- Take-home proprietary EMC design software

- Free optional design evaluation of your product

- Instructors with over 75 years combined engineering experience

Call Carol at 847-537-6400 for more information.

December 16, 2009

Bill Stumpf, D.L.S. Site Manager,

Helps Write New Standards

The role of ANSI Accredited Standards Committee C63® – EMC is to develop definitions and methods of measurement of electromagnetic noise and signal strengths, determine levels of signal strength, levels of unwanted sources, limiting ratio of noise (and/or unwanted sources) to signals, and develop methods of control of, and guidelines for influence, coupling and immunity. There are currently twenty C63 standards developed by this committee or currently in development or re-issue. Bill is an active volunteer on Sub-Committees SC-1 Techniques & Development, SC-6 Accreditation/Conformity Assessment, and SC-8 Medical Device EMC Test Methods. Development of C63.10 is being done by members of SC-1.

Work on the C63.10 standard began in 2006. The C63.10 standard is intended to consolidate and develop procedures for testing the compliance of a wide variety of unlicensed wireless devices. Until now, the test procedures were scattered about in different FCC publications, application notes, and guidance documents, which has caused confusion regarding the testing of devices and inconsistent test results. The first edition of this standard is slated for publication later this year.

November 20, 2009

D.L.S. Names Mitch Gaudyn

Conformity Assessment Manager

D.L.S. Electronic Systems, Inc. in Wheeling, IL names Mitch Gaudyn Manager of their Conformity Assessment Compliance Testing Group.

Mr. Gaudyn will oversee the day-to-day operations and management of the Product Safety testing arm of D.L.S., covering UL, CSA, CE, CCC, C Tick, BSMI and other global testing standards and requirements. Mr. Gaudyn comes from Charles Industries, where he has been the Product Manager for OSP Telecom and Other Electronic Products. For more information on D.L.S. and their global testing programs, go to www.dlsemc.com or call 847-537-6400.

May 19, 2009

Free Evaluation for New Medical Standard

D.L.S. Conformity Assessment, Inc. offers compliance testing to the new IEC/EN 60601 Third Edition Medical Device Standard scheduled to go into effect September 2009. To ensure your products are compliant to the new requirements, contact D.L.S. today at 847-537-6400 for a free evaluation.

March 31, 2009

D.L.S. Electronic Systems in Wheeling, IL is Now

an Authorized iNARTE Testing Center

D.L.S. Electronic Systems, Inc. is proud to announce that it has met the requirements of the International Association for Radio, Telecommunications and Electromagnetics, Inc. and is declared to be an authorized testing center for iNARTE. An authorized test center is a facility which meets the iNARTE guidelines to offer exams to FCC commercial license applicants, as well as to professional engineers who want to become iNARTE certified.

D.L.S. will be giving the exams at 8am on Saturday, May 16, 2009 at their facility at 1250 Peterson, Wheeling, IL 60090. Registration must be completed online at www.inarte.org by Friday, May 1, 2009 and fees must be paid directly to NARTE. Seating is limited, so please register early.

For more information, please contact Brian Mattson at 847-537-6400.

February 10, 2009

Lightning and HIRF Update

D.L.S. Electronic Systems, Inc., a testing laboratory in Wheeling, IL, has added to their already extensive Lightning and High Intensity Radiated Fields (HIRF) testing capabilities. They can perform all indirect lightning effects testing for the commercial aviation industry under the recently updated standard RTCA-DO-160F and for the military and defense marketplace’s recently updated standard MIL-STD-461F. D.L.S. has also increased HIRF testing capabilities to 2000 V/M (volts per meter) pulsed up to 18 GHZ (Gigahertz). This is in addition to the 200 V/M continuous wave (CW) susceptibility testing normally done at D.L.S.

The testing performed simulates unwanted energy that may affect electrical and electronic equipment found on aircraft, ground equipment, communications, surveillance, weapons and guidance systems. Increased awareness of potential high energy electromagnetic threats have established a need for this type of testing.

D.L.S. is an accredited Electromagnetic Compatibility (EMC) testing and consulting organization through National Voluntary Laboratory Accreditation Program (NVLAP) under the National Institute of Standards and Technology (NIST) and is ITAR (International Traffic in Arms Regulation) registered. D.L.S. recently celebrated its 25th anniversary. For more information, contact Jack Black at 847-537-6400.

February 1, 2008

Expanding EMC Capabilities

Progression of the rebuilding of Site One at our Genoa City, Wisconsin location.

December 18, 2007 |  December 18, 2007 |

January 4, 2008 |  January 4, 2008 |

January 9, 2008 |  January 9, 2008 |

January 10, 2008 |  January 21, 2008 |

January 21, 2008 |  January 21, 2008 |

January 21, 2008 |  January 21, 2008 |

January 22, 2008 |

January 8, 2008

Free EMC Layout and Design Software

to Solve Even the Most Complex EMC Issues

As part of the curriculum in Donald Sweeney and Roger Swanberg’s EMC by Your Design Seminar/Workshop students will use, and then take home free-of-charge, a copy of the proprietary EMC Layout and Design software program created by the instructors. This proven software package addresses design considerations from component level, through circuit boards, to enclosure level, including cabling and interconnects and enhances the theories presented both in the class and in the Mardiguian textbook. The four-day seminar/workshop is presented in a practical, hands-on style providing the step-by-step design process to avoid EMC problems. After the workshop attendees can put their acquired knowledge to immediate use in an optional, free, 45-minute design evaluation of their own product.

To register, call Carol at 847-537-6400.

October 9, 2007

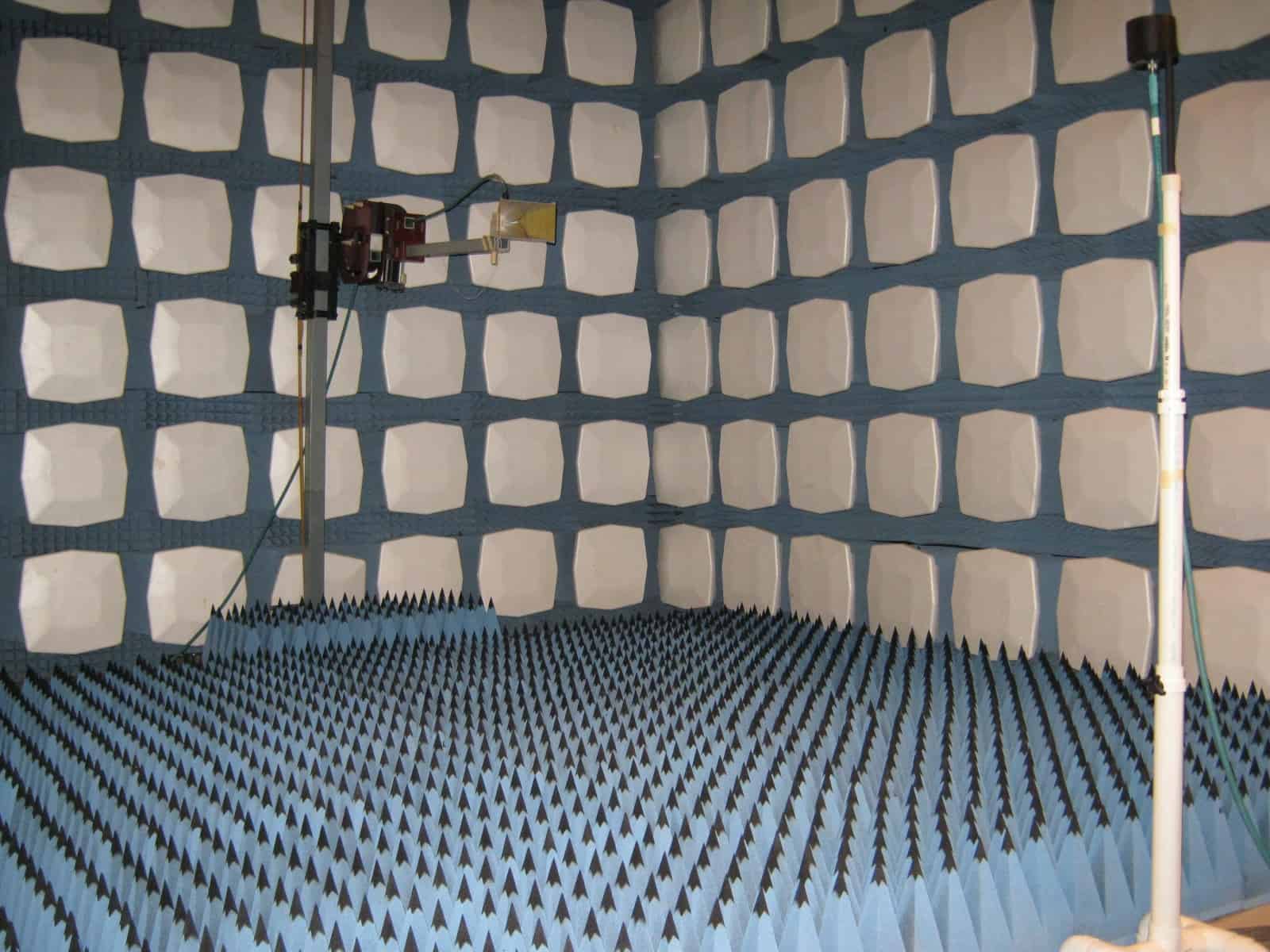

New 3-Meter Chamber

D.L.S. Electronic Systems, Inc. has added a new full-automated, state-of-the-art, semi anechoic 3-meter chamber to its Wheeling, IL testing facility. This chamber, listed with the FCC, allows for a streamlined measurement process, at frequencies that excced 1 GHz. More products currently have clock/crystal frequencies >108 MHz, and the FCC requires these frequencies to be tested beyond the former 1 GHz limit. D.L.S. offers global compliance programs for EMC and Product Safety, providing a one-stop shop.

May 31, 2007

HHA Safety Standard 60335-1’s new EMC requirements significantly increase severity

of immunity testing.

A recent amendment to the IEC/EN 60335-1 Standard, which covers household and similar appliances, added EMC requirements to this safety standard. These requirements apply to electrical appliances which incorporate protective electronic circuits, those which have a switch with an off position obtained by electronic disconnection and those with a switch that can electronically be placed in a stand-by mode. The new requirement significantly increases the IEC 61000-4-x severity levels mandated in the EMC standard EN 55014-2. Some of these requirements became mandatory on October 1, 2006, while the rest are currently scheduled to become mandatory on October 1, 2007.

These new requirements were added to address the increased use of electronically controlled switching in these types of products. This type of switching has a potential to be interfered with which may cause inadvertent operation, and related safety hazards.

The new requirements significantly increase the IEC 61000-4-x severity levels mandated in the EMC Standard EN 55014-2. As an example, products without protective/standby electronic switches are required to meet EN 61000-4-5 Surge levels of:

+ 1kV Differential Mode (line-to-line)

+ 2kV Common Mode (line-to-ground)

For products with these electronic switches, the levels are increased considerably to:

+ 2kV Differential Mode (line-to-line)

+ 4kV Common Mode (line-to-ground)

In addition to the surge test example above, there are many other immunity tests affected, including radiated susceptibility and ESD.

Since there is no grandfather provision, manufacturers of household and similar appliances should have their products evaluated, and potentially tested, immediately. This will assure they are prepared for the new IEC/EN 60335-1 EMC mandates becoming mandatory in October 1, 2007. For more information call Steve Grimes at 847-537-6400.

July 17, 2006

New Approach to EMC Learning

Textbook teaching has its place in learning EMC fundamentals. But real-life experience relating these fundamentals to actual situations is essential. Donald L. Sweeney and Roger Swanberg, with over 75 combined years of experience in the field of EMC, now bring these fundamentals to life through hands-on, practical application to real life products.

To register call Carol at 847-537-6400.

(If you cannot attend this class, the next one will be April, 2007)

February 6, 2006

CCC Mark Cost Saving

China Compliance Certification Program

D.L.S. recently hosted a Chinese delegation in an effort to create a smooth inter-country transition for electrical and electronic devices. As a result we have a new CCC China EMC and Safety Compliance Program which has been implemented into our global certification program. This will save you time and money as similar tests required by various standards and various countries can be run simultaneously.

To help this program run smoothly, we have representatives in Shanghai, Shenzheng and Beijing, which work directly with CQC/CEMC and the different test labs in China. Our Chinese representatives have worked hard to establish a good relationship with the Chinese compliance agencies.

We also have a full-time safety engineer, Yaqing Liu, at our Wheeling, IL facility who reads, writes and speaks fluent Chinese. She communicates regularly with our representatives in China, thereby simplifying your work selling into the Chinese market. As an example, she helped one of our clients get their CCC mark in one and a half months, including their initial factory inspection.

Our China compliance program applies to products in the following categories:

ITE Equipment

Medical Equipment

Transmitter/Receivers

Household and Similar Appliances

Audio/Video Equipment

Wireless Communications

Electric Tools

Lighting Electrical Appliances

Alarm Systems

Telecommunication Terminal Equipment.

Let us know what can we do for you.

October 18, 2005

D.L.S. Offers

Free EMC/Product Safety Testing

for New Low Frequency Magnetic Requirement

EN 50366:2003 for HHA Equipment

Required as of February 2006

A recent change to the HHA Low Voltage Directive added Household and Similar Electrical Apparatus (EN 50366:2003) testing requirements. This involves low frequency testing from 10 Hz to 400 kHz for magnetic fields that are emanating from electrical devices. Items applicable include, but are not limited to:

- Household and similar appliances

- Restaurant equipment, fryers and ovens

- Commercial scrubbers and cleaning equipment

- Water heaters and amusement devices.

There is no provision for a grandfather clause on existing certifications.

July 5, 2005

D.L.S. Expands Military & RTCA Capabilities to

include Lightning Induced Transient Susceptibility

D.L.S. Electronic Systems Inc. of Wheeling, IL now offers complete cable testing for RTCA DO-160 E, Section 22 Multiple Burst/Multiple Stroke Lightning Induced Transient Susceptibility for all wave forms.

For more information call 847-537-6400.

November 12, 2004

D.L.S. attains status of fully certified

CSA-APD Agent

D.L.S. Conformity Assessment, Inc., of Wheeling, Illinois, has attained the status of a fully qualified Agent of CSA International. This means D.L.S. now provides product safety testing at their Wheeling, IL facilities for both US and Canadian requirements to CSA, UL, and other North American standards. D.L.S. is the first lab to achieve this status.

This new relationship provides an additional fast option for manufacturers of Medical and Laboratory equipment. It provides prompt localized testing by D.L.S. with the product certification of CSA International. D.L.S. is also able to help manufactureres of ITE, Industrial, Household, Audio-Visual and other electric and electronic equipment reach their market quickly.

For 84 years, the CSA safety mark has been proudly displayed on electrical and electronic equipment of all types, items you see and use every day. CSA, a global leader in product safety compliance programs, has been designated as an NRTL (Nationally Recognized Testing Laboratory) by OSHA, a status identical to other safety agencies in the United States.

D.L.S. now provides testing and certification for the well-known CSA Mark, CSA US, CSA Canada, CSA Canada and US, as are depicted in the marks below. This is all in addition to the large variety of EMC testing D.L.S. offers. Manufacturers can now meet their goal of getting high quality Safety and EMC compliance testing all in one place, all at one time.

For more information call Jack Black at 847-537-6400.

August 31, 2003

D.L.S. Electronic Systems, Inc. awarded

NARTE Certified Organization status

On August 31, 2003, the National Association of Radio and Telecommunications Engineers bestowed upon D.L.S. Electronic Systems, Inc. the rare accreditation of NARTE Certified Organization. To achieve this accreditation, 70-100% of all engineers and technicians must be NARTE certified. To become certified, engineers and technicians must meet rigid educational, experience, testing, peer and supervisory endorsements. D.L.S. currently has 16 NARTE certified engineers.

This accreditation allows all who come to D.L.S. the confidence that their test engineers are highly educated and well trained. The accreditation is particularly helpful to those working on Department of Defense projects, including NAVAL Air Command and NAVAIR, as they are explicitly required to work with NARTE certified engineers to assure competent testing and results. D.L.S. is the largest of only three existing NARTE Certified organizations in the world. D.L.S. tests to MIL STD 461, RTCA DO-160, FCC, CE, IEC, VCCI and many other requirements. More information can be found at www.dlsemc.com or by calling Jack Black at D.L.S. Electronic Systems, Inc. at 847-537-6400.

For further information regarding the NARTE Certified Organization Status, contact The National Association of Radio and Telecommunications Engineers, Inc., P.O. Box 678, Medway, MA 02053, phone 508-533-8333, fax 508-533-3815. The National Association of Radio and Telecommunications Engineers, Inc. describe the NARTE status as “a signal to customers, competitors and employees that the company is committed to EMC excellence. It is visible testimony that the company supports, encourages, emphasizes and values the certification process.”

Click links to learn about our MIL STD 461 Testing

and

If you’re interested in becoming NARTE certified, test your knowledge with NARTE Question of the Week.

August 30, 2002

NARTE Exam Tips

Engineers and technicians who want their NARTE certification now have a painless and easy way to prepare for the NARTE exam. D.L.S. Electronic Systems, Inc. in cooperation with NARTE (the National Association of Radio and Telecommunications Engineers, Inc.) has developed a web site with a “NARTE Question of the Week.” Each Monday a new question will be listed on the web site. Just copy/click the link in your web browser: iNarte Question of the Week and bookmark it as a favorite. Review the question of the week. Decide on your answer and click to see if you are correct.

Here are some tips:

Don Sweeney, Sr. EMC Engineer and NARTE Certified EMC Engineer, who took the test to prove to himself that he deserved being grandfathered as a NARTE engineer and technician, suggests that you consider the following while reviewing the question.

- Read the question. Then ask yourself, “What are they really asking for?”

- Read all the answers. Don’t stop at the first one you come to that looks correct, but instead choose the best one after reading all the listed answers.

- As you go through the questions week after week, think about what resource materials you might want to bring with you to the final test, since it is an open-book test.

When you begin to feel prepared for the test, look for a link to NARTE enabling you to get your application form and other materials. This link is on the question page.

For additional information contact Carol Gorowski at D.L.S. Electronics Systems, Inc. at (847) 537-6400.

What is NARTE EMC certification and why would someone want it? In the late l980’s the Navy through NAVAIR wanted a way of knowing their equipment was being tested correctly. NARTE, the National Association of Radio and Telecommunication Engineers, was contacted to set up a program for both EMC Engineers and Technicians. Initially through a grandfathering process, the certification requirements could be met by personnel having a specific level of experience and three individuals in the industry to vouch for their level of experience and expertise.

After the initial grandfathering was over, all future NARTE EMC engineers and technicians are required to pass a written examination. The exam takes an entire day and covers many areas of EMC. The standard way to prepare is to order study guides and work sample questions.

With D.L.S. now listing the NARTE question of the week on the web, a prospective engineer or technician can simply click the web site and study a new question each week. This should be a painless and simple way for someone with the basic knowledge and experience to prepare for the examination.

December 5, 2000

D.L.S. Now a Conformity Assessment Body

for the EMC and R&TTE Directives

D.L.S. Electronic Systems, Inc. has been designated as a Conformity Assessment Body (CAB) for the EMC and R&TTE Directives under the Mutual Recognition Agreement between the United States and the European Union. Under article 10(2) of the EMC Directive, a CAB in the US can perform the same operations as a European Competent Body.

D.L.S., One of the first labs to complete EU EMC testing and to provide Technical Construction Files (TCF’s) for their customers, is now recognized as a CAB. Having been nominated for CAB statues by National Institute of Standards (NIST) in 1998, we have completed the preliminary phases and may now operate independently of other entities to meet customer’s needs. The implication of the CAB status is that it qualifies D.L.S.to operate as the equivalent to a European Competent Body for EMC and Notified Body under R&TTE for radio transmitters.

During the past 24 months D.L.S. has been doing various EMC activities such as testing products, writing Technical Construction Files (TCF’s) and submitting them to a European Competent Body during the transition.

In its role as a CAB (a European Competent Body equivalent) D.L.S. generates and reviews TCF’s and issues certificates of conformity to manufacturers without the involvement of another European Competent Body. Performing as a Notified Body, D.L.S. can also advise customers on how to meet the R&TTE Directive for radio transmitters.

D.L.S. which has been in operation for the last 17 years, is one of the largest EMC labs in the world under one roof and can accommodate almost any size project for EU CE Marking, FCC, EMC and radio transmitters.

June 22, 1999

D.L.S. Electronic Systems, Inc. Expands

Test Services to Include Product Safety

In order to offer customers one-stop shopping for EMC and Product Safety, D.L.S. Electronic Systems, Inc. has formed a subsidiary, D.L.S. Conformity Assessment, Inc. and now offers in-house Product Safety testing.

Services include:

· Knowledge of the latest changes in rules, regulations and test procedures.

· Assistance in designing for Safety and EMC.

· Testing and evaluation of commercial, household, and industrial products.

· Consultation with both Safety and EMC experts.

· Ensuring changes made during testing are compatible with both Safety and EMC requirements.

· Coordinating on-site agency witness testing with UL, CSA & TUV.

· Minimizing delays and need for re-testing by monitoring agency progress and providing quick

response to their requests.

D.L.S. Conformity Assessment, Inc. is managed by Tom Brenner under the direction of Donald L. Sweeney. Tom brings 14 years of experience in product safety testing and evaluation. In addition to his work with UL and TUV, he also has industry experience, which provides him with valuable insight on avoiding the regulatory complications manufacturers often face.

For further information please call 847-537-6400.

August 12, 1986

D.L.S. Approved as FCC Test House

On August 12, 1986 National Bureau of Standards announced its approval of D.L.S. Electronic Systems, Inc. as an FCC test house. This means that FCC reports issued by D.L.S. Will bear the insignia of NBS which signifies to the customer the validity of their testing. The insignia, NVLAP stands for National Voluntary Laboratory Accreditation Program which is directed by the National Bureau of Standards, U.S. Department of Commerce.

NBS evaluated equipment, personnel, and testing procedures at D.L.S. And were very pleased with their findings. The test engineers were given an in-depth interview during which time their technical knowledge of FCC rules and regulations were evaluated as well as their understanding of the testing procedures. All equipment was inspected including the review of calibration records for each piece of equipment. NBS visited both the Glenview, IL lab and the open field site were validated and the site attenuation was reviewed. Both radiated and conducted testing was observed and testing procedures were evaluated for the maximizing of emissions through cable movement, equipment orientation, and antenna height.

D.L.S. feels very honored to receive the approval of the National Bureau of Standards and is proud to be recognized as a qualified test house. D.L.S. Offers a variety of testing and consulting services including FCC parts 15, 18, and 68, verified and certified, and MIL STD susceptibility and emissions. D.L.S. is owned and operated by Donald L. Sweeney, Senior EMC Engineer who is nationally known for his problem solving abilities.